Our Processes

Different projects demand diverse solutions. That's why we provide a range of die casting options to match each unique application. At the end of the day, if you can envision it, we're confident we can create it.

HOT CHAMBER

DIE CASTING

Utilizing a rapid cycle time and melting pot within the machine, our hot chamber die casting process is ideal for metals with low melting points, ensuring efficient and consistent production.

COLD CHAMBER

DIE CASTING

Perfect for metals with high melting points, our cold chamber die casting offers enhanced strength and durability, while allowing for intricate design capabilities.

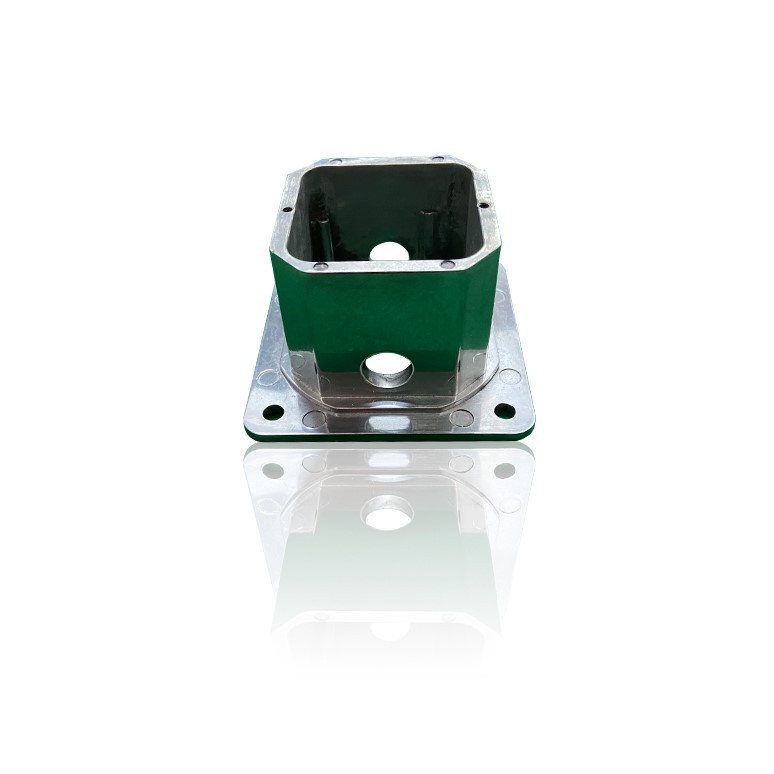

Sample Die-Cast Parts

Clamp Tub

Black E Coat / Black Anodize

Watch Case

Nickel Plating

Sprue Bushing

Powder Coating

Handle

Nickel Plating

Wrench

Bead Blast & Blue Anodize

Bicycle Bracket

Chromate Treatment

Mobile Housing

Bead Blast & Red Anodize

Housing

Milling

Bezel

Sand Blast & Hard Black Anodize

Our Die-Casting Materials

ZINC

Known for its exceptional ductility and resistance to corrosion, zinc is ideal for intricate designs and prolonged durability.

Zamak 2

Zamak 3

Zamak 5

Zamak 7

ZA8

ALUMINUM

Lightweight yet strong, aluminum offers excellent thermal conductivity and resistance to rust, making it versatile for various applications.

383

B390

Technical Specifications

Need all the details? Get specific with our comprehensive alloy equivalent chart and material properties guide.